Thrust 3: DEVICES AND APPLICATIONS

Focus of the thrust:

The purpose of this thrust is to demonstrate ideas and achievements proven in small scales in the laboratory in Thrusts 1 and 2, in substantially larger scales for appreciation and acceptance by potential industry partners. Some of the achievements in Thrusts 1 and 2, which are in mm scales, will pose different engineering problems when scale-up is attempted. Hence, a separate thrust is required to tackle engineering issues that do not exist in Thrusts 1 and 2. Though, the devices and systems produced here are also meant for use in the laboratory, they are of substantially large scales (cm scale).

This thrust began execution later than the other two as efforts were focused to solve scientific problems first. When we have made good progress on the scientific front, we embarked on Thrust 3 with well-defined deliverables. Below is a summary of the targets at present.

Scaling up Synthesis and Processing of PV Materials

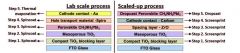

After commissioning the operation of our CREATE laboratories and assessing our capabilities, we decided to aim for a 30 cm2 perovskite solar cell. There are advantages and disadvantages associated with fabrication of large area solar cells. The advantages stem from the higher output power that could be generated per substrate, which leads to lower material cost to achieve a particular output power. The main disadvantage is related to the fabrication process used in Thrust 1 previously. Some modifications have to be introduced as the process used previously was not scalable to this extent. The lab-scale process utilized in Thrust 1 and the new scaled-up process of Thrust 3 are compared in Fig 1. New process steps have to be used in place of some steps in the lab-scale process to ensure that the whole fabrication process is economical and scalable to commercials levels.

Figure 1: Standard device fabrication procedure for lab-scale (left) and scaled-up (right) perovskite solar cell

Photovoltaics/Photoelectrochemical Cell (PEC) Tandem Device for Solar Fuel production

The objectives of demonstration of fuel, in particular solar water splitting, are: (i) to demonstrate ideas and achievements proven in Thrusts 1 and 2 in mm scales, (ii) addressing the engineering issues in scale up of the water splitting system that could produce significant amount of H2. The main experimental tasks of this work could be divided into three parts: a) Anode Development, b) System Development, and c) Anode Evaluation. This is schematically shown in Fig 2.

Figure 2: Thrust III Work Structure, main focus on: 1) Anode Development, 2) System Development, and 3) Anode Evaluation.

The first phase of theproject incorporates the design and fabrication of a prototype of the scaled-up water splitting system. It is a compact, modular fish tank sized test-bed. This was produced and commissioned with full validation tests (see Fig 3). Preliminary work on photoanode production and testing has also been completed. The second phase of the project consist of optimization of the photoanode for the Plug-and Play electrodes concept for the tandem cell design (Photoanodes + Pt + perovskites ) or (Photoanodes + Pt +CZTS/CIGS) in the next phase of the Solar Driven Water Splitting system development.

Figure 3: PEC water splitting system set up using Mo/BiVO4 photoanode and Pt as cathode.